Which Handrail is Right for Your Project?

- Madeleine Mankey

- Nov 14, 2024

- 5 min read

Updated: Mar 12

Handrails have been a specialty of Kite Group for the last 20 years. In that time, we have been able to refine our products on offer, resulting in quality, modular systems that fit a variety of purposes. But how to choose which system is right for your project? Read on to find out more about the different benefits of each kind of handrail system.

· Ball Standard System

· Tube Clamp System

· DDA Clamp System

· ModiFix System

· GRP Handrail System

· How can I improve the Performance of my Handrail?

Ball Standard System

This handrail system is robust, resistant to corrosion and has high durability. The system can have a range of clamps and standards available level or raked at various angles to suit your needs.

Benefits:

Made of steel, with high tensile strength and durability

Simple, robust and aesthetic design

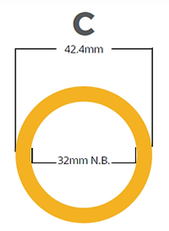

Tube, standards and clamps in range of sizes available, A – E

Need for some extra clamps is eradicated by Ball Standard design

Suitable for heavy duty applications, such as warehouses, construction sites, petrochemical plants etc.

Straightforward installation

To consider:

Requires periodic inspection and maintenance to prevent rusting and wear

Does not meet DDA standards for most public access handrails due to ball standard design

Tube Clamp System

This handrail system retains many of the benefits of the ball standard system, but is even more modular. Instead of ball standard posts, more tube is used, making it an ideal choice for non-standard sizes of handrail. Thanks to tube clamps such as the Multi Swivel Elbow (166) and Double Swivel (167), any angle can be accommodated for in this handrail system.

Benefits:

Fully modular to any height or angle required

Made of steel, with high tensile strength and durability

Simple, robust and aesthetic design

Tube and clamps in range of sizes available, A – E

Suitable for unique locations, requiring modular solutions, e.g. undulating hills – see our Edinburgh Tram project for more information

Straightforward installation

To consider:

May not be as suitable for heavy duty applications as the Ball Standard handrail

Requires periodic inspection and maintenance to prevent rusting and wear

Does not meet DDA standards for most public access handrails due to ball standard design

DDA Clamp System

Sharing much in common with the Tube Clamp System, the main difference with a DDA handrail is the clamps used to provide a smooth, continuous finish. It shares the material and aesthetic of the Tube Clamp system, but opens up opportunities to all public access areas.

Benefits:

Smooth, sleek run that is specifically designed to meet Disability Discrimination Act (DDA) standards, ensuring accessibility for all users.

Made of steel, with high tensile strength and durability

Modular design, available to suit size C tube

Suitable for areas with public access, such as hospitals, public transport stations, schools, offices etc.

Straightforward installation

To consider

Powder coating will help to improve visibility of this handrail.

Can be more costly than the Galvanised Tube Clamp System

ModiFix System

A transformative railing system patented by Kite designed to reduce cost and environmental impact. Laser-cutting technology eliminates the need for welded components, which reduces both the carbon footprint and health and safety risks for installers.

Benefits:

Cost-saving, innovative design that uses up to 20% less steel

Reduced environmental impact, reducing carbon footprint of projects

Fully modular with range of sizes available

Suitable for heavy duty applications, such as warehouses, construction sites, petrochemical plants etc.

Straightforward installation

To consider:

Precise and accurate design must be agreed upon at order stage

As the system does not provide a flush top rail, it is not suitable for DDA-compliant public access handrails

Due to laser-cutting, this system may take longer in production than other handrail systems

GRP Handrail System

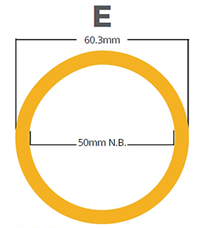

This handrail system is comprised of Glass Reinforced Plastic, sometimes called fibreglass. It is a hardy, lightweight alternative to steel that suits a range of applications. We supply tube and clamps in yellow GRP.

Benefits:

GRP material is highly resistant to corrosion, unlike steel which requires regular inspection and maintenance. For this reason it is suitable for places exposed to harsh and wet conditions, such as harbours, bridges and other coastal areas.

GRP is also non-conductive which makes it an ideal candidate for use in electrical plants

Lightweight and easy to handle, making it easier to transport to site and install than steel counterparts

To consider:

Available only in size E

May initially cost more, however delivers savings over time as the system is long lasting and low maintenance

How can I improve the Performance of my Handrail?

There are other ways to customise your handrail to suit the specific needs of your project. We will go into three options in detail – powder coating, addition of kick plate, and addition of mesh panels.

Powder coating

Powder coating is a customisation option that both protects steel and allows for different coloured handrails

By powder coating in a colour that contrasts with the background, you will be improving the visibility of your handrail

Unlike painting, powder coating allows for an even coating with no running or dripping, and does not contain solvents or heavy metals that are harmful to the environment

It is worth bearing in mind that powder coating a handrail system will increase the lead time of an order

Kickplate

Also called Kickboard, Toe Plate or Toe Board, kickplate is required on handrails fitted to elevated walkway areas, such as mezzanine floors or roof perimeters

They run along the bottom of a handrail and are designed to prevent items falling from these areas to the ground

Kickplate can come in galvanised steel or GRP to suit the handrail system you have installed

Mesh Panels

Wire mesh panels can be installed onto a handrail to close up the open spaces on a handrail system

This adds an extra safety measure to prevent falls, for example to safeguard children or animals

It is worth considering that mesh panels will be fabricated specifically to your handrail design, and may add to the lead time of a project

Overall, there is much to think about when choosing a handrail system to install. Ultimately, context will be instrumental in your decision-making. Ball Standard systems are the most heavy duty option, while a Tube Clamp system can cater to handrails required in more hilly terrain.

If the handrail services an area of public access, then a DDA handrail is the prime choice. If the area is exposed to conditions of sea spray, a GRP handrail would be a smart and lasting fit. If reducing environmental impact is a priority, ModiFix should be considered. Intended use, location and budget will dictate the right system for you.

If you need any technical guidance to decide on which handrail system that could suit your project, speak to Kite today to start moving forward with confidence.

Follow Kite Group on LinkedIn to read about Kite’s posts and commitment to sustainability.

We offer Bespoke Service, Technical Support and Same Day Dispatch! Get in Touch today!

Comments